Project Description

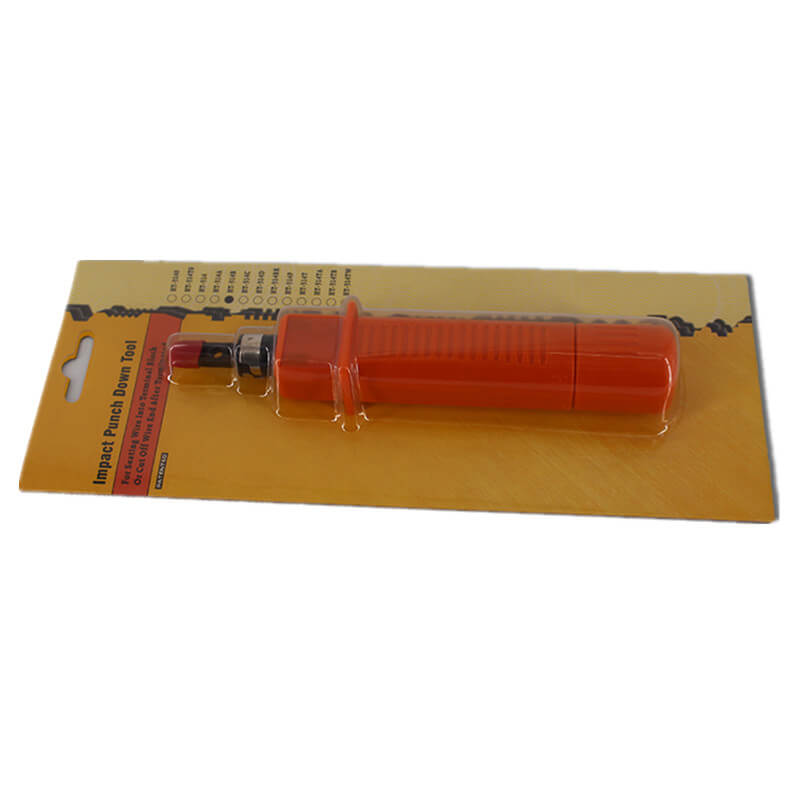

PUNCHING TOOL 914B

| Part Number | Description |

|---|---|

| BLNT-914B | Punching Tool, 914B |

PUNCHING TOOL 314B

| Part Number | Description |

|---|---|

| BLNT-314B | Punching Tool, 314B |

PUNCHING TOOL

| Part Number | Description |

|---|---|

| BLNT-KD-1 | Punching Tool, Krone Type |

Introduction

The Punching Tool is an essential device for creating precise holes in various materials. Whether in metalworking, electrical installations, or construction projects, the Punching Tool plays a crucial role. It not only enhances work efficiency but also ensures high precision and consistency in every task. Its versatility and durability make it the ideal choice for professionals and DIY enthusiasts alike, enabling users to achieve superior quality and efficiency across a wide range of applications.

Product Features

-

Versatility: Suitable for a wide range of materials, making it an indispensable tool for various projects.

-

High Precision: Ensures accurate cutting and punching, delivering consistent results every time.

-

Durability: Constructed from high-quality materials, the tool offers a long lifespan, even with frequent use.

-

Ergonomic Design: Provides comfortable handling and reduces fatigue, allowing for extended use without discomfort.

Product Categories

-

Manual Type: Ideal for small projects and DIY enthusiasts, offering ease of use and portability.

-

Hydraulic Type: Provides a more efficient solution for professionals, delivering enhanced power and precision.

-

Electric Type: Suitable for large-scale industrial applications, ensuring high performance and productivity.

Usage Guide

Step-by-Step Instructions

-

Preparation:

- Select the appropriate Punching Tool type for your material.

- Ensure the tool is clean and in good working condition.

-

Setup:

- Secure the material firmly on a stable surface.

- Adjust the tool settings according to the material thickness and desired hole size.

-

Operation:

- Align the tool with the marked spot on the material.

- For manual tools, apply steady pressure to create the hole.

- For hydraulic or electric tools, activate the mechanism to punch through the material.

-

Completion:

- Inspect the hole for accuracy and clean any debris.

- Turn off and store the tool safely after use.

Safety Tips

- Always wear protective gear, such as gloves and safety glasses.

- Ensure the work area is well-lit and free of obstructions.

- Keep hands and fingers away from the punching area during operation.

- Regularly check the tool for any signs of wear or damage before use.

- Follow the manufacturer's instructions and guidelines for maintenance.

Common Applications

-

Metal Fabrication:

- Used for creating precise holes in metal sheets and components, essential for manufacturing and assembly processes.

-

Electrical Installation:

- Ideal for punching holes in panels and enclosures, facilitating the installation of switches, outlets, and wiring.

-

Construction:

- Utilized for making accurate holes in building materials, supporting tasks such as framing and ductwork installation.

Details Photos